The Sunday Signal: AI for Good, Healing Healthcare, and Steel Without Coal

Essential Insights on Tech’s Impact, Leadership Lessons, and Navigating Human Potential Issue #17 – Sunday 10 August 2025

⏱️ 10 min read

The Bottom Line Up Front

From AI-designed materials that push the limits of physics, to algorithms helping NHS clinicians make rapid life-saving decisions, to Sweden’s move towards steelmaking without coal, we are witnessing a pattern. When innovation is applied with purpose, it can cut through decades of entrenched limitations. This is not about hype or futurism. It is about solving real problems in ways that were impossible until now. The message is clear. The right technology, in the right hands, can deliver progress that is both rapid and profound.

When AI Designs the Impossible

New materials have always marked turning points in human civilisation. The Bronze Age brought the first true metal alloys, transforming tools, weapons and trade. Steel production in 19th-century Sheffield reshaped industry, enabling railways, bridges and entire cities to rise. In the 20th century, aluminium, carbon fibre and advanced composites gave us aeroplanes, satellites and a space industry.

These breakthroughs did not happen quickly. Developing a new material traditionally takes decades. It involves a cycle of human-led experimentation, laboratory trials, and gradual refinement. High-strength steels took years of iterative improvement. Carbon fibre was first produced in the 1960s, but it remained expensive and limited to specialist uses until well into the 1980s and 1990s.

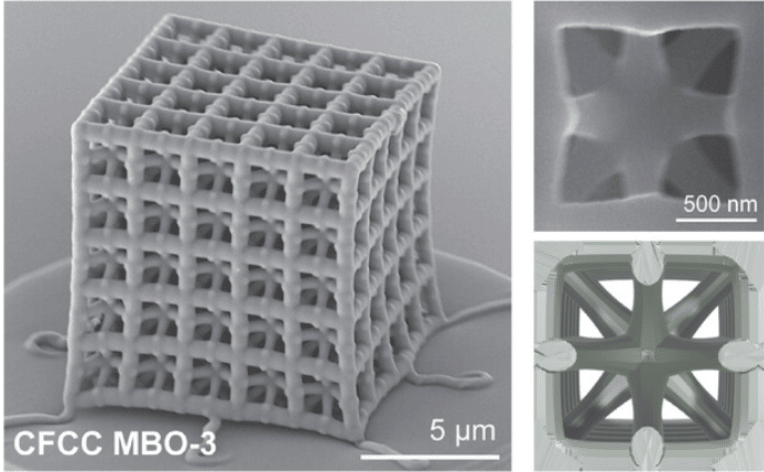

The work of scientists at the University of Toronto, in collaboration with Caltech, shows that this model may be about to change completely. They used AI to design carbon-based nanolattices as strong as steel but light enough to rest on a soap bubble. These intricate structures were then created using nanoscale 3D printing, proving that they work in practice, not just in simulation.

The difference is not only the performance of the material but the way it was discovered. Instead of building prototypes over years, the researchers fed physical constraints, performance requirements and atomic behaviours into an AI system. The algorithm generated designs that were then filtered and tested. Many of these would never have occurred to a human researcher because they lie outside our normal intuition for geometry and structure.

By starting with AI-driven exploration, scientists can search vast design spaces in days rather than years. This approach does not remove the need for human expertise, but it radically changes where human effort is applied. Instead of trying to guess what might work, researchers can focus on testing the most promising candidates the AI has already identified.

The applications are vast.

In aerospace, airframes could be made far lighter without sacrificing strength, reducing fuel use and emissions.

In automotive manufacturing, lighter but stronger crash structures could improve both safety and efficiency.

In construction, earthquake-resistant buildings could be made with less material.

In medicine, implants could be lighter, stronger and tailored to the exact needs of each patient.

There are still hurdles. The Toronto team’s claims, including that the material is ten times stronger than steel and up to 95 per cent air, will need independent verification. Scaling production to industrial levels will take time and investment. But the pattern is set.

Every leap in materials science has enabled decades of innovation. If AI can compress discovery cycles from decades to months, then the pace of industrial transformation in the coming years may surpass anything we have seen before.

AI in the NHS: A Personal Case for Change

Adapted from my regular column in this week’s Yorkshire Post

Two months ago, a close family member was taken to hospital with a suspected stroke. Anyone who has lived through that moment knows the tension. Every minute matters. A delay in treatment can mean the difference between full recovery and permanent brain damage.

I had previously built an AI model designed for stroke management. Sitting at their bedside with my laptop, I began entering vital signs, test results, medications and observations from the nursing staff. The AI rapidly generated diagnostic insights and treatment recommendations.

When the consultant arrived, I asked them to review the AI’s suggestions. They listened carefully as I explained the source, then stepped away to check the calculations manually. They returned shortly afterwards, confirming the accuracy of the AI’s recommendations. To describe them as surprised would be an understatement.

In this case, my relative had suffered a transient ischaemic attack, a temporary blockage in blood flow to the brain. They were discharged after an overnight stay. But I left the hospital convinced of two things.

The first is that AI can act as a powerful support for clinicians. It is not about replacing their judgement but enhancing it. An AI system can hold vast amounts of knowledge in memory, cross-checking thousands of variables in seconds, and flagging potential issues early.

The second is that the NHS should not be slow to act on this. In conditions like sepsis, where every hour of delay increases the risk of death, rapid identification is critical. AI can analyse patterns across vital signs, test results and patient history, alerting staff to dangers well before they become visible to the human eye.

Later that evening, I decided to apply the same process to my own health data. I uploaded a decade of blood test results from my time in the United States. The AI flagged several patterns and concerns that my GP had never mentioned. Since returning to the UK and adopting a healthier lifestyle, those patterns had already improved.

We often talk about the NHS in terms of resources, staffing and budgets. Yet here is a clear opportunity to improve outcomes without proportionally increasing costs. AI can help every doctor and nurse work at the top of their ability, reduce mistakes, and free time for the human side of care. In a system under pressure, that is not just valuable. It is essential.

Steel Without Coal: Sweden Shows the Way

Steel is everywhere. It forms the frame of our buildings, the rails of our transport networks, and the machinery of our factories. It is also one of the dirtiest industries on earth, responsible for roughly 8 per cent of all global CO₂ emissions.

The problem lies in the blast furnace. For over a century, steel has been made by smelting iron ore with coking coal. The coal serves as both a heat source and a chemical agent, removing oxygen from the ore and producing carbon dioxide as a byproduct.

Sweden’s SSAB, working with LKAB and Vattenfall, has developed a different approach. The HYBRIT project replaces coal with hydrogen produced using renewable electricity. When hydrogen reacts with the oxygen in the ore, the only byproduct is water vapour.

This is no longer just theory. Volvo has already built trucks using fossil-free steel from SSAB. The company aims to produce 1.3 million tonnes a year by 2026. If rolled out across the country, the process could cut Sweden’s emissions by 10 per cent and Finland’s by 7 per cent.

The challenge is scaling it. Green hydrogen requires large amounts of renewable power, and the cost of production is still higher than coal-based methods. But with carbon pricing increasing and renewable energy becoming cheaper, the economic case will strengthen quickly.

The implications go beyond the environment. Countries that can produce green steel at scale will have a competitive advantage in export markets, especially as customers and regulators demand low-carbon supply chains. In the 19th century, nations that mastered steelmaking led the industrial age. In the 21st century, those who master fossil-free steel will lead in sustainable manufacturing.

The lesson is clear. Even industries that seem impossible to decarbonise can be transformed when innovation, policy and investment align. The question is whether the rest of the world will follow Sweden’s example in time.

This video explains the process:

🚀 Final Thought

From Possibility to Action

The three stories this week are not just about science and engineering. They are about choice. AI-designed materials that could reshape entire industries already exist. AI tools that can enhance the judgment of NHS clinicians and save lives are already here. Fossil-free steel production is no longer an aspiration but a working industrial process.

The challenge is not invention. It is deployment. Far too often, we treat transformative breakthroughs as curiosities rather than imperatives. We wait for costs to fall, for standards to form, for someone else to prove it works at scale. In the process, we lose precious time.

History is full of examples of what happens when those in power hesitate. Britain’s early advantage in computing after the Second World War was squandered by lack of investment and strategic vision. Kodak’s digital camera was shelved to protect its film business, only for the company to collapse. The Royal Navy resisted steam power until rivals forced its hand.

We cannot afford to repeat those mistakes on the technologies that will define the next century. AI in healthcare will save lives if it is embedded into practice now, not in a decade. Green steel will cut emissions and secure competitive advantage if governments and industry commit to scaling it immediately. AI-designed materials could lead to an entirely new industrial base if we invest in manufacturing capacity rather than admiring laboratory samples.

The future belongs to those who act. Those who wait will have the same fate as every other industry, company or nation that mistook comfort for security. The opportunity is here. The responsibility is ours. The cost of inaction will be measured not only in lost markets and missed profits, but in lives and a planet that could have been saved.

Until next Sunday,

David

David Richards MBE is a technology entrepreneur, educator, and commentator. The Sunday Signal offers weekly insights at the intersection of technology, society, and human potential.

© 2025 David Richards. All rights reserved.